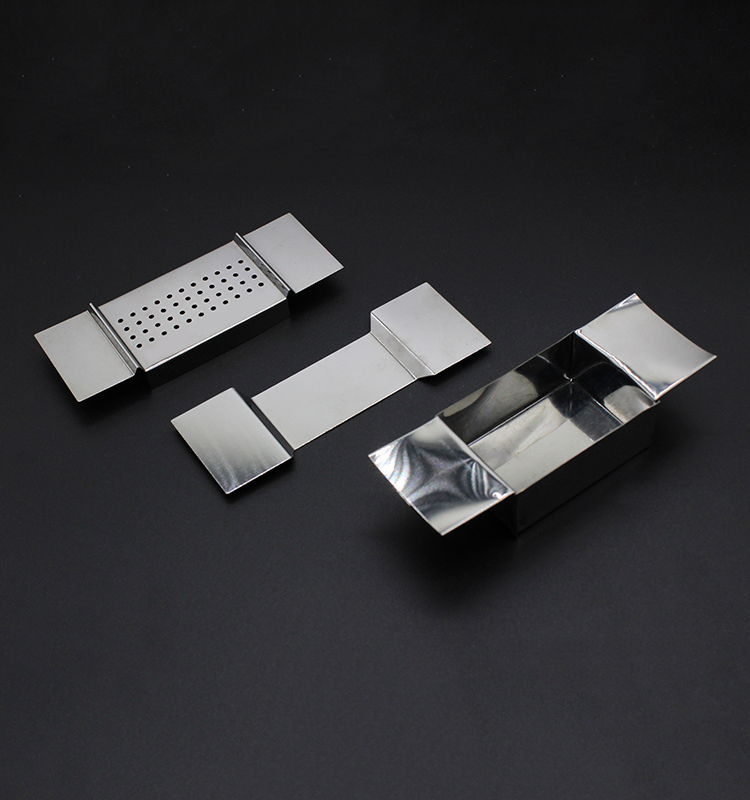

Molybdenum boat 1. Specification: Made according to the scale provided by the user. 2. Material: MO-1 or molybdenum based alloy. Density: 10.15-10.2 g/cm3. 3. Production method: The board is rolled, bent, and riveted. 4. Adaptable temperature: Can be used under conditions above 1400 ℃ -1900 ℃. 5. Large processing range: ≠ 7-8mm or less × fifty × two hundred × 1000.

2024

LNG

LNG