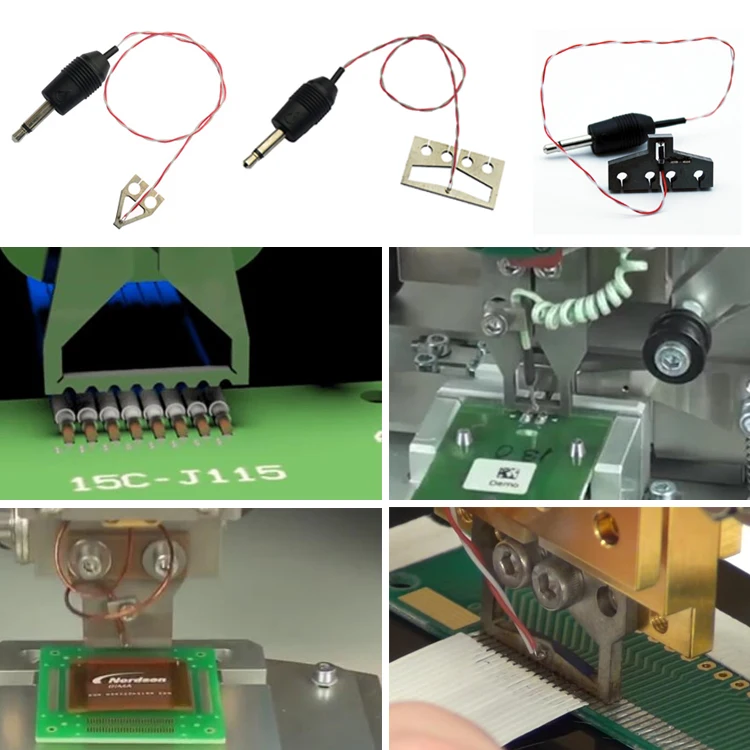

Electrode cap is an electrode for spot welding head welding, mainly used in the welding industry of resistance spot welding equipment, such as fixed spot welding machine, hanging spot welding head and robotic spot welding machine, etc., due to the sleeve it is above the electrode connecting rod, so it is called the electrode cap. Under normal circumstances, the electrode cap is made of chromium zirconium copper, and some of it is made of diffused copper. After many times of welding, the worn parts need to be repaired and replaced, which is a direct consumable for welding. In the process of processing , the most used raw material for the production of electrode caps is chromium zirconium copper. The chromium and hair added to pure copper will increase the surface and temperature of the coating cap more effectively, and the conductivity is better. Electrode caps with diffused copper are mainly used for welding of galvanized sheets. Chromium will react with the zinc in the galvanized sheets to a certain extent, which can generate substances similar to copper, which has a great impact on the quality of welding. This problem can be solved by dispersing copper. There are two ways to inspect the electrode cap, one is a destructive inspection method, and the other is the opposite, which is a non-damage inspection. Mainly it is to test the mechanical properties of the electrode cap master batch and welding materials.

2021

LNG

LNG