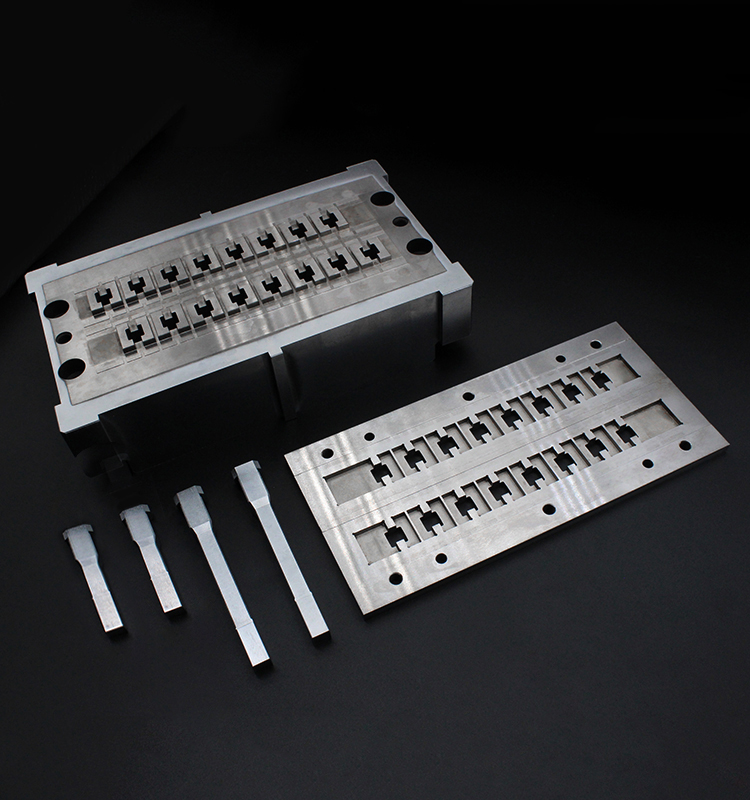

Spot welding head design principles: different welding materials, different welding point requirements, different welding energy, and different spot welding head designs required. General spot welding heads are divided into three parts, namely the power connection part and the transition part As with the discharge part, different designs have different effects on connection, gathering and discharge, which will lead to different welding effects and service life. Generally speaking, a good discharge effect means a good welding strength and a low welding voltage. Under the same parameters, the service life of the corresponding spot welding head will be reduced.

2021

LNG

LNG