MENU

LNG

LNG

Domestic because of backward production technology about the world popular 2 component evaporation boat can not be produced,only a single 3-component evaporation boat can be made, It’s formula is to increase a certain proportion of aluminum nitride on the basis of 2 components, high formula density this formula has high density and many materials,which is only limited to traditional professional application, while products with strict evaporation quality requirements cannot be satisfied. However,some companies increase tungsten, calcium carbonate, calium oxide, zirconium oxide and other methods on the basis of the 3 components, which completely go into the misunderstanding of the components and have no way to control the quality.

The addition of 2 components is widely used in the world, which is reconginized by customers in terms of quality and power.Because the composition is as long as boron nitride and titanium diboride, the quality is more controllable in the production process.The resistivity is very accurate.The evaporation power of 2 components is that any other component can’t compare with beauty.2 components have low density, less meterials, and simple production and processing.Today, when human beings vigorously protect the environment, low carbon and environmental protection has bacome the responsibility of each of us.

1. The heating part of the evaporation boat is too hot at high temperature and the heating time is too long, resulting in carbonization.(Common situation is open flame operation, first carbonization, then cracking) The problem of operation method is very likely

2.The heat shrinlable tube has a notch at the incision, which shortens the process, splits ans extends( Especially for the tube with higher shortening ratio) processing method problems are unlikely

3.Heat shrinlable tube Itsealf quality problem.The possibility is quite big.

4.Is there any sharp foreign matter in the tube that cuts the heat shrinkable tube suring shortening.

5.For example, the original diameter is 1.8, and the actual diameter is 1.6.

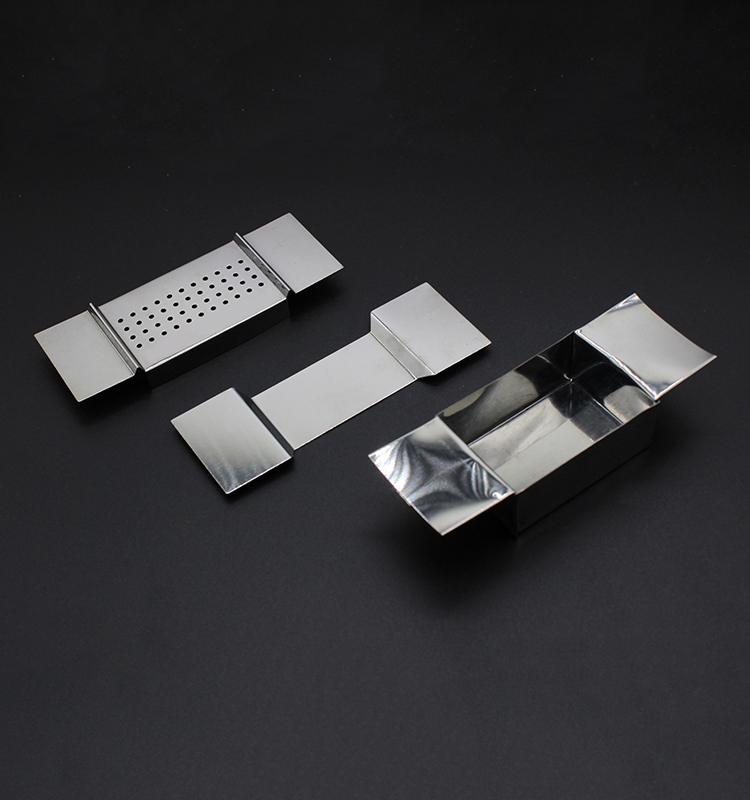

The raw material of evaporation boat is BN, TiB2, ALN ceramic powder.TiB2 is a project developed for 863 programs in our country, and is a new type of ceramic materials supported by high and new technologies in our country.BN and TiB2 are non-oxide high-tech engineering ceramics materials, which have attracted international attention and research in the past ten years.China’s key laboratory of information composite new technology has won the first prize of scientific and technological progress and the thrid prize of scientific and technologyical progress of bulding materials Bureau, and Ningxia Machinery Research institue has won the sponsorship of innovation fund od Ministry of Science and Technology.In terms of the three main powder sources used in the production of evaporation bas, he omestic research has been successful and there is no need to import them.Foreign market price is extremely expensive, such as TiB2 powder price of 200-300 dollars/kg.

Evaporation boat products uses:widly used in packaging industry to produce coating (plated paper, plastic, glass, textile,etc),It’s also used in the industries of electronic sound device, integrated circuit coating and kinescope coating, It is the main component of vacuum vapor plating (Aluminum) membrane equipment and is an aluminum evaporation boat.