MENU

LNG

LNG

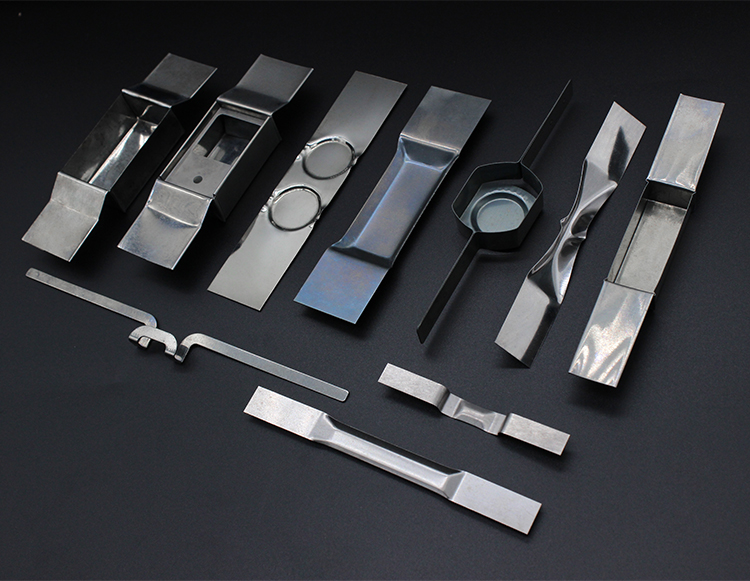

With the rapid development of the world economy, the categories of industry are becoming more and more complete, and the evaporation boat has gradually infiltrated into various industries unconsciously. In recent years, it has a high reputation in domestic shopping malls. As the main product of our company, the evaporation boat firmly takes the lead in the evaporation boat industry with its highly competitive skills and product quality advantages.

However, it is worth noting that many users have many problems in operation, which also reduces the longest service life of the evaporation boat to a certain extent, and is not conducive to the best function of the evaporation boat. To solve this problem, I will introduce the key operation points of the conductive ceramic evaporation boat produced by our company in detail, so as to help users better play the role of the conductive ceramic evaporation boat.

1. The two rows of clamps shall be aligned and the appearance shall be smooth and clean.

2. The end face or side face shall be made of graphite paper to ensure good electric touch and heat conduction.

3. Close the power supply for about two minutes until the evaporation boat cools to dark red, and start to turn off the vacuum.

4. The touch point of the aluminum wire should be located at one third to two fifths of the boat length.

5. The new evaporation boat shall not be heated too fast for the first time to avoid affecting the venting.

6. When the new evaporation boat is used for the first time, the aluminum feeding speed should be gradually increased from about 75% of the normal value, and the power should be gradually reduced to reach a large aluminum spreading area.

7. The new evaporation boat should be heated for 15 minutes for the first time, and the aluminum should be sent to start evaporation plating by the above method.

8. When each roll is evaporated and plated, stop feeding aluminum first, and then turn off the power 30-60 seconds later.

In order to give full play to the best function of the evaporation boat and achieve the longest service life, please pay attention to the following key operations:

1. When each roll is evaporated and plated,

2: Stop aluminum feeding first

3: Turn off the power after 30-60 seconds

4: After closing the power supply for about 2 minutes, cool the evaporation boat to dark red, and start to turn off the vacuum.

The first evaporation boat in Dongguan is made of high-purity and high-quality raw materials, which ensures that the materials have good chemical properties. The international advanced vacuum hot pressing sintering method is selected to ensure the excellent physical properties of the product. The sintering process adopts two-way pressurization mode to ensure the consistency of product bulk density. Digital control of production equipment to ensure the stability and consistency of product quality. The unique process formula, optimized composition and structure, enhanced the thermal shock resistance and bending strength of the evaporation boat, and improved. The spreading ability and evaporation efficiency of aluminum liquid can enhance the corrosion resistance ability of aluminum liquid and prolong the service life.

If you have any questions about the evaporation boat, please consult us. Welcome.