MENU

LNG

LNG

Technological Breakthroughs and Application Prospects of Metal Etching Process in MLCC Carrier Tape Industry

In the manufacturing of multilayer ceramic capacitors (MLCCs), carrier tapes serve as critical substrates for supporting ceramic dielectrics and electrodes, where their precision and performance directly impact capacitor consistency and reliability. Traditional laser cutting or die-stamping processes are limited by machining accuracy (±20μm) and thermal stress, making them unsuitable for producing ultra-miniature 01005 (0.4×0.2mm) MLCCs. Metal etching technology, with its unique advantages in precision microstructure fabrication, is bringing revolutionary opportunities to the MLCC carrier tape industry.

1. Micron-Level Pattern Accuracy

Etching achieves ±3μm pattern tolerance, precisely controlling the etching depth (5-50μm) of carrier tapes (e.g., polyimide/PET composites) using ferric chloride/nitric acid systems, accurately replicating electrode patterns with 5μm linewidth. Compared to laser processing, it avoids carbonized edges that cause dielectric loss.

2. Complex Structure Machining

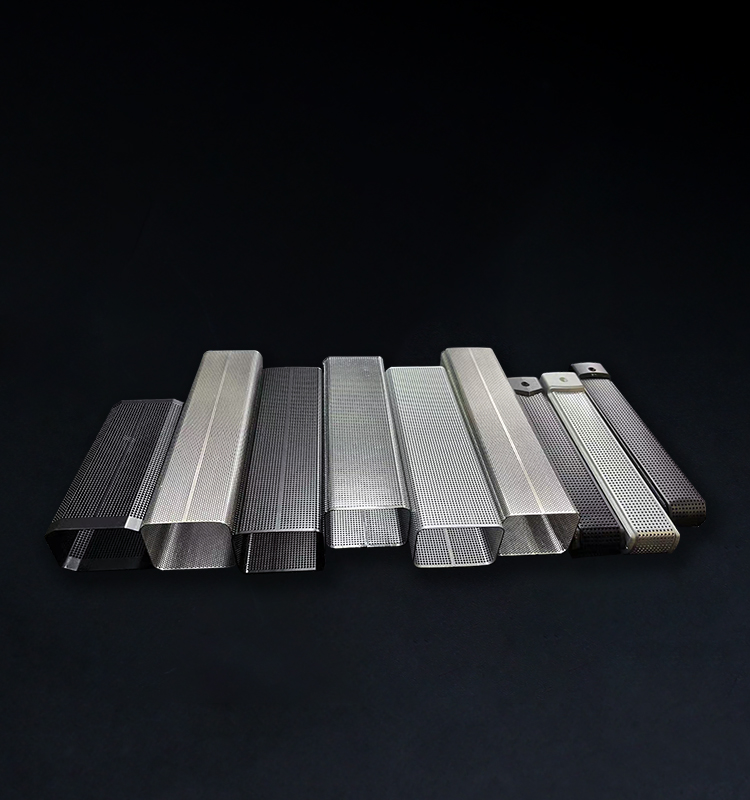

Supports 3D shaping such as stepped grooves and honeycomb support structures. For example, etching a 12μm-deep buffer grid on the tape surface reduces ceramic dielectric layer thickness variation to within 0.8%, significantly improving MLCC capacitance consistency.

3. Batch Processing Efficiency

A single etching operation can simultaneously process 300mm×300mm carrier tapes with a pattern density of 5,000 units per sheet, tripling efficiency compared to traditional step-by-step processing—ideal for large-scale production of automotive-grade MLCCs.

A three-phase strategy is recommended:

Metal etching technology enables MLCC carrier tapes to evolve from passive substrates to active performance regulators. As 5G and electric vehicles demand higher MLCC performance, mastering this technology will help companies break into high-end markets. Accelerating collaboration with equipment suppliers and end-users to build differentiated competitiveness is strongly advised.

(Note: Technical terms like "MLCC," "Q-factor," and "μm" remain in standard English notation for industry consistency.)