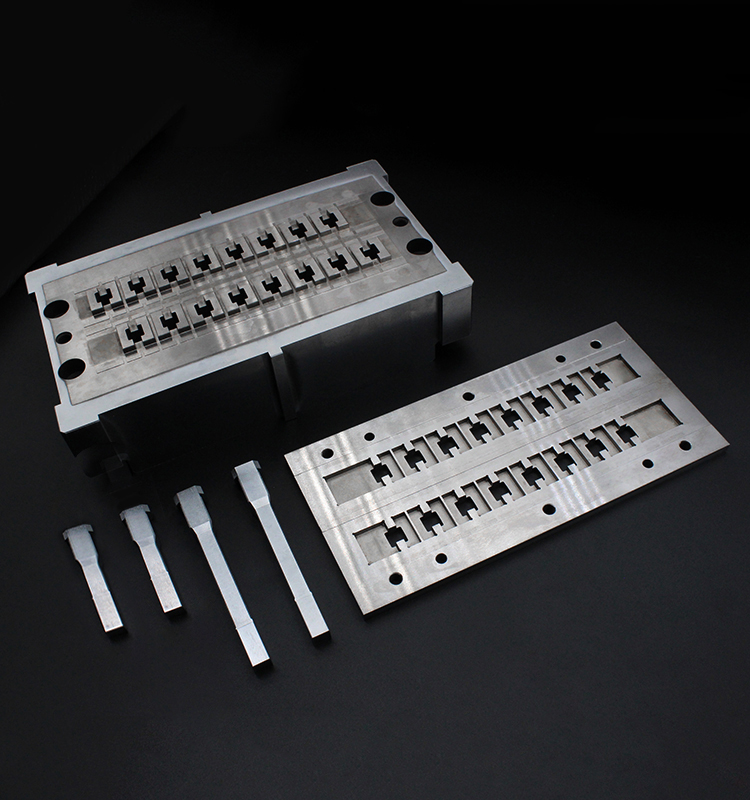

There are two shapes of precision spot welding tips: sector and conical. The conical shape can imporve the rigidity of the bumps and prevent premature crushing when the electrode pressure is high; It can be also reduce the splash caused by excessive current density. But sector shape bumps are usually used. In order to prevent the extruded metal from remaining around the bumps and forming gaps between the plates, bumps with annular overflow grooves are sometimes used. In multi-point projection welding, the inconsistent height of the bumps will cause the imbalance of the current at each point and make the joint strength unstable. Therefore, the height error of the bump should not exceed ±0.12mm. If the preheat current is used, the error can be increased.

2023

LNG

LNG