MENU

LNG

LNG

The resistivity of spot welding joints is not only dependent on the metal variety, but also on the heat treatment status, processing method, and temperature of the metal. Touch resistance exists for a short period of time and is generally present in the early stages of welding. It is composed of two reasons: there is a high resistance coefficient oxide or dirty material layer on the surface of the workpiece and electrode, which can cause significant obstruction to the current. An excessively thick layer of oxides and dirt can even prevent current from conducting. Under very clean exterior conditions, due to the micro unevenness of the surface, the workpiece can only form touch points in parts of the rough surface. The folding of the current line at the touch point. The reduction of the current path increases the resistance at the touch point. Compared with Rc and Rw, the resistance between the electrode and the workpiece, Rew, is relatively small because the resistivity and hardness of copper alloys are generally lower than those of the workpiece, and therefore have a smaller impact on the composition of the molten nucleus. We rarely consider its impact.

1. The influence of welding current on heat generation is greater than both resistance and time. Therefore, during the welding process, it is a parameter that needs to be strictly controlled. The main causes of current changes are fluctuations in the grid voltage and changes in the impedance of the secondary circuit of the communication welding machine. The impedance change is due to a few changes in the shape of the circuit or the introduction of different amounts of magnetic metal in the secondary circuit. Regarding DC welding machines, changes in the impedance of the secondary circuit have no significant impact on the current.

2. The impact of welding time: In order to ensure the size of the weld nugget and the strength of the solder joint, the welding time and welding current can complement each other within a certain range. In order to achieve a certain strength of solder joints, high current and short time (strong conditions, also known as hard standards) can be selected, as well as low current and long time (weak conditions, also known as soft standards). The choice of hard standard or soft standard depends on the function, thickness, and power of the welding machine used. There is an upper and lower limit for the current and time required for different functions and thicknesses of metals in a spot welding head, which is used as the standard.

3. The influence of electrode pressure on spot welding head. The electrode pressure has a significant impact on the total resistance R between the two electrodes. As the electrode pressure increases, R significantly decreases, while the increase in welding current is not significant and cannot affect the heat generation reduction caused by the decrease in R. Therefore, the strength of the solder joint always decreases with the increase of welding pressure. The solution is to increase the welding pressure while also increasing the welding current.

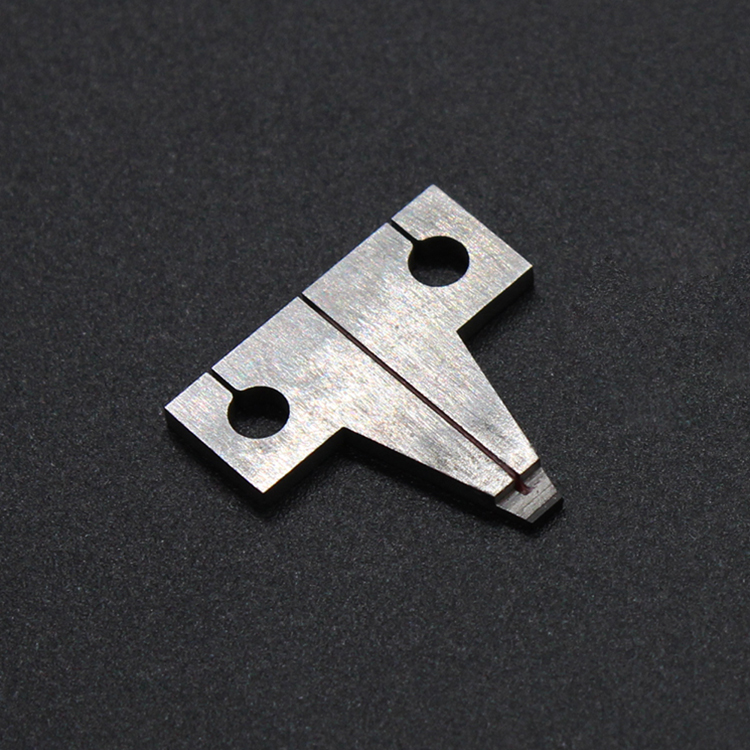

4. The influence of electrode shape and material function.