MENU

LNG

LNG

LNG

LNG

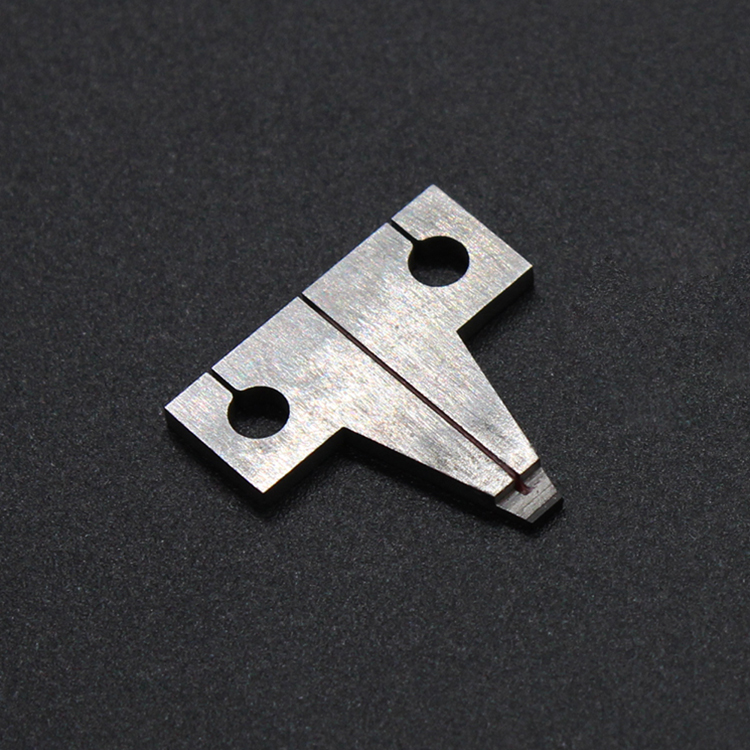

Molybdenum is a rare refractory metal material with excellent properties such as high melting point, high hardness, corrosion resistance, low expansion coefficient, and good thermal conductivity. It has been widely used in many industries such as aerospace, nuclear industry, medical, chemical, metallurgy, etc. Molybdenum has a melting point of 2620 ℃ and is a refractory metal. Due to the strong bonding force between atoms and the high strength at room and high temperatures, it is also widely used in high-temperature resistant components such as furnaces, rocket engines, missiles, etc.

Alloy steel, stainless steel, tool steel, and cast iron are the main application areas of molybdenum, and their production determines the demand for molybdenum. Adding molybdenum can improve the corrosion resistance of stainless steel. Adding molybdenum to cast iron can improve its strength and wear resistance. Nickel based high-temperature alloys containing 18% molybdenum have the characteristics of high melting point, low density, and low coefficient of thermal expansion, and are used in the manufacturing of various high-temperature components in aerospace and other fields. Molybdenum is widely used in electronic devices such as tubes, transistors, and rectifiers. Pure molybdenum wire is widely used in high-temperature electric furnaces, electric discharge machining, and electric discharge wire cutting. Molybdenum is used to manufacture radio and X-ray equipment. Molybdenum has extensive applications in other alloy fields and chemical industries. Adding molybdenum to alloy steel can improve its elastic limit, corrosion resistance, and permanent magnetic properties. Molybdenum oxide and molybdate are excellent catalysts in the chemical and petroleum industries.

Language

Language

Mailbox:brian.he@soucua.com

Mailbox:danny.ng@soucua.com

Mailbox:rose.zhang@soucua.com

Mailbox:smion.siew@soucua.com

Mailbox:mila.lin@soucua.com

Postcode:523300

Address:No. 11, Hengjiao Hengling Street, Hengjiao Village, Shijie Town, Dongguan City, Guangdong Province, China

Copyright ©2020Dongguan Soucua Hardware Electronics Co., Ltd.

All Rights Reserved