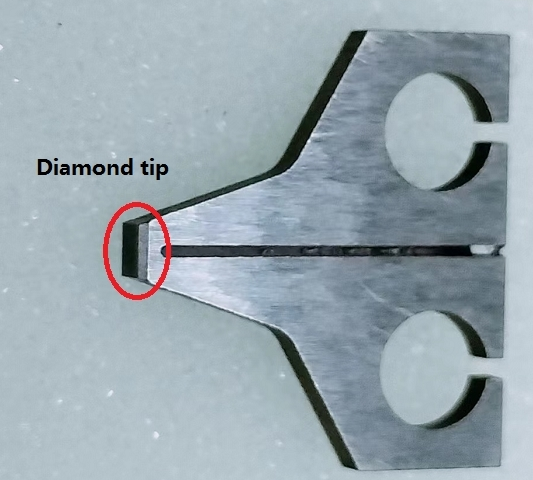

1.the method of grinding the welding head

When the welding head is not strong or the wire is brought up, the first should be to grind the welding head, not to increase the parameters. When grinding the welding head, be careful not to use too much force to grind, only need to use a grinding disc or W5 Use fine sandpaper to lightly polish the bottom of the welding head with one or two strokes.

2.Do not loosen the welding head frequently

There is insulating glue in the middle of the welding head and then loosening it will affect the contact position of the welding heads on both sides, causing the welding effect to be very bad. Therefore, it is strongly recommended that the welding head is installed and used until the welding head can not be used before taking it out. Do not frequently disassemble and assemble the welding head in the middle.

3.The clamping part of the welding head clamp should be clean

Because the welding uses a large current, the reason that a large parameter is often required is that the center of the welding head clamped by the welding head clamp is very dirty, which seriously affects the flow of current. Therefore, it is recommended to clean the area once a month.

LNG

LNG